NEOZANT™ Materials of the Future

Mechanical Properties

High Impact Resistance

NEOZANT™ toughness, making it ideal for applications requiring impact durability.

Fatigue Resistance

Withstands cyclic loading better than many traditional thermoplastics.

High Flexural Strength

Maintains rigidity under load, suitable for structural parts.

NEOZANT™ Impacted with 130 ft-lbs

Toughened Epoxy Impacted with 15 ft-lbs

Thermal and Chemical Resistance

Wide Temperature Range

Increased temperatures above 120 degrees possible, and great performance in cryogenics

Low Water Adsorption

Enhances dimensional stability and longevity in wet environments

Chemical Resistance

Resistant to a broad range of solvents - Acids, Bases, and Halogens comparable to Fluoropolymers

Design Versatility

Paintability & Adhesion

Bonds well with coatings and paints; Works well with in-mold coatings; Key advantage in automotive and aesthetic components.

Thermoset Stability

As a thermoset polymer, NEOZANT™ maintains form under stress and heat without softening; Low creep.

Permeability

Significantly outperforms conventional materials in dielectric loss, making it better for high-frequency applications.

Substantially lighter - an advantage in aerospace applications where weight reduction improves range, fuel efficiency, and performance.

Excel in mechanical toughness and durability, making it ideal for ground radomes, UAVs, subsonic aircraft, and situations with debris/hail impact risk

Offers faster, lower-cost, and scalable production, making it attractive for commercial and mass-produced defense platforms.

TransmissIbility

NEOZANT™ surpasses epoxy and cyanate ester with lower dielectric loss, higher strength, lighter weight, and cost-effective production, making it ideal for advanced radome applications.

Superior Dielectric Performance

High Mechanical Strength

Lightweight Design

Optical Clarity

Cost-Effective Processing

Resin-only Processability

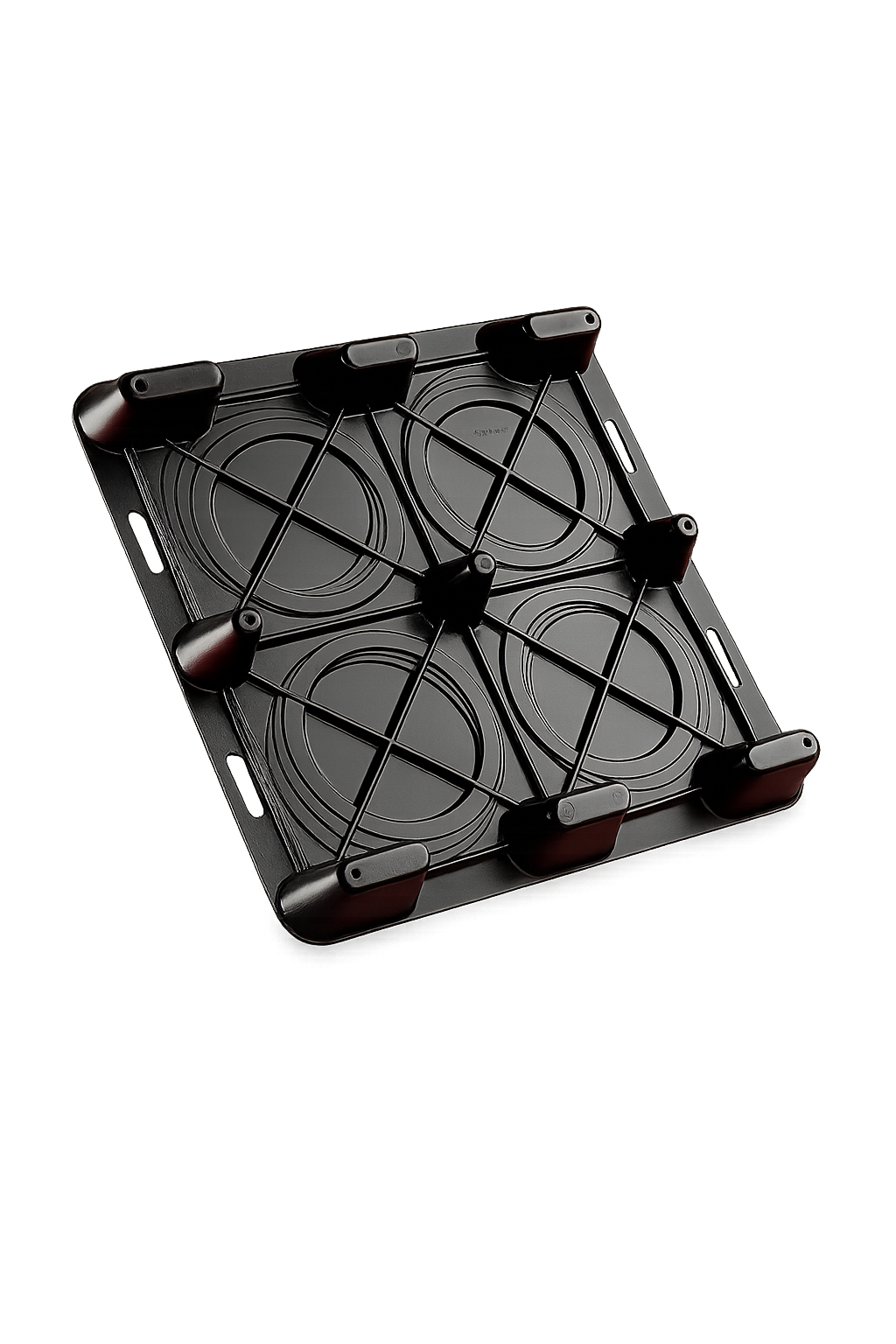

Low-Pressure Molding with NEOZANT™

NEOZANT™ is processed using Reaction Injection Molding (RIM), offering distinct advantages:

Lower Tooling Costs: Significantly reduced compared to traditional injection molding.

Complex Geometries: Enables large, thick-walled, and intricate part designs.

No Mold Pressure Required: Unlike urethane molding, NEOZANT™ eliminates the need for high-pressure molds, resulting in a significant reduction in CAPEX requirements.

Operator-Controlled Cure Times

Fast Cycle Times: Enables rapid production for high-volume manufacturing.

Large Part Production: Supports the creation of large-scale components with ease.

Composite Processability

Ability to produce thick wall composites with much-improved resistance to delamination (toughness)

Ability to make high fiber volume composite (viscosity)

VARTM infuses in less than 10% of the time of normal epoxies (viscosity)

Material can be heat-formed like thermoplastics

Permeability is much better than other polymers

NEOZANT™: Unleashing Superior Strength and Versatility in Every Application

Unlock NEOZANT™’s Power Across Industries

Elevate your operations with our cutting-edge resin.

Connect with Us Today!